Explore advanced rotary die solutions for nonwovens and specialty converting—engineered with 25 years of expertise to deliver cleaner cuts, extended tool life, and dependable high-speed performance.

Our Services

Die Rebuilding & Repair

Our expert technicians restore performance by precisely resharpening blades and re-calibrating tolerances to original specifications.

Die Quality Assurance & Compliance

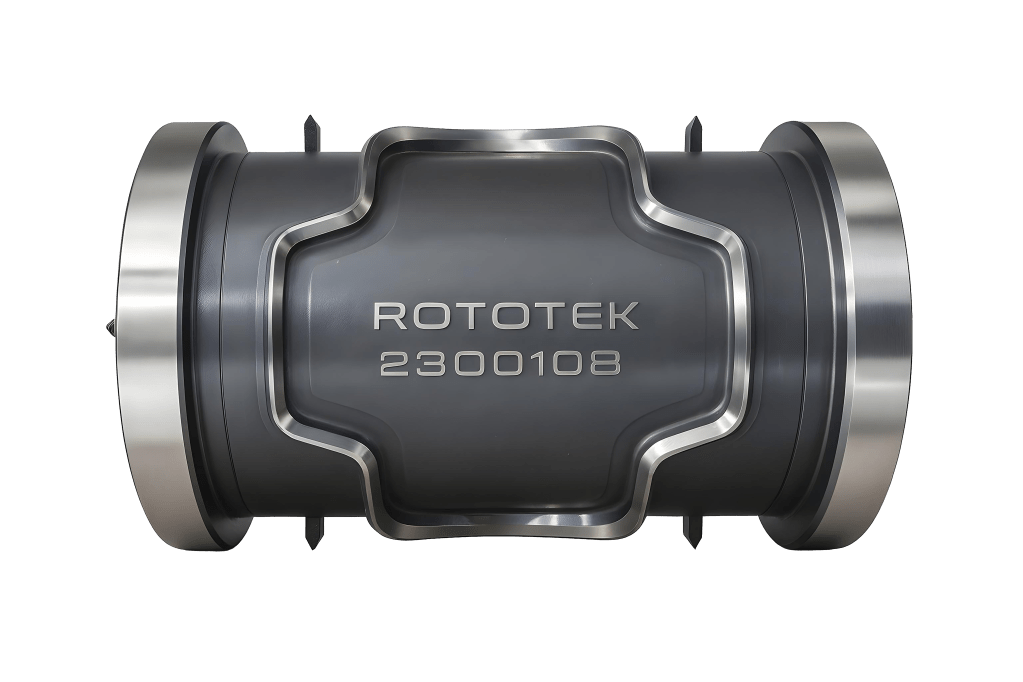

Rototek utilizes advanced precision measurement instruments and detection systems to ensure every die meets stringent specifications—both prior to installation and throughout its operational lifecycle.

Custom Rotary Design

Rototek combines proven design principles with advanced materials engineering to deliver high-precision dies, meticulously crafted to meet the exact requirements of your application.

FAQs

How Does Your Rebuild Process Work?

Every rebuild begins with a meticulous inspection to evaluate damage, wear, and overall structural integrity. Our experienced technicians conduct detailed dimensional checks and visual analyses, ensuring no issue goes unnoticed. Based on these findings, we develop a precise, comprehensive action plan that guides the entire rebuild process with accuracy and efficiency.

By leveraging advanced machining technology and Rototek’s proven sharpening techniques, we restore critical geometries and cutting edges to their original specifications and tolerances, ensuring optimal performance and extended tool life.

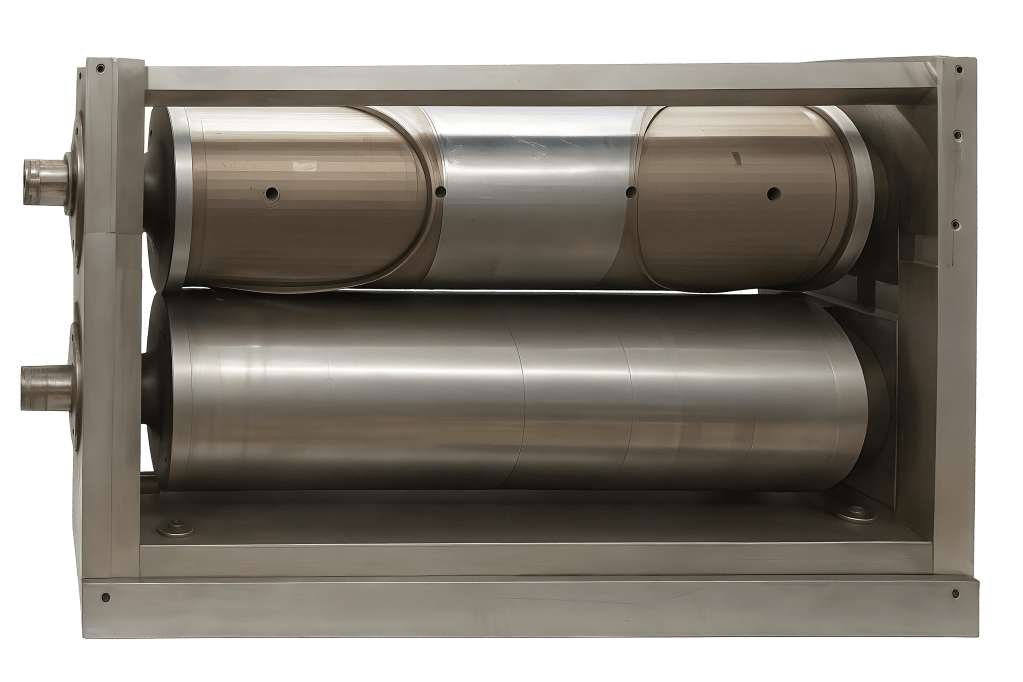

We replace or recondition key components—including anvil rolls, cutting blades, and bearing surfaces—to enhance reliability, restore precision, and significantly extend the operational life of your die.

How Does Your Custom Rotary Die Design Process Work?

Leveraging in-house CAD modeling, we simulate full-cylinder deflection to verify accuracy and stability. This ensures every die ships ready to perform immediately, eliminating the need for re-shimming and reducing setup time.

Tailored Geometries for Exact Specifications

Every application is unique. That’s why we engineer dies to match your precise product requirements, line speeds, and operational parameters. Whether you’re working with intricate label designs or wide-format flexible films, our custom geometries ensure optimal performance and uncompromising accuracy.

Materials Selected for Durability

We carefully select and recommend the optimal die steels, coatings, and wear-resistant materials tailored to your converting process. Each choice is made with precision, factoring in the abrasiveness of your substrates to maximize tool life, maintain cutting accuracy, and ensure long-term reliability.

Tight Tolerances & Material-Specific Edge Profiles

Building on Rototek’s legacy of precision, our engineers design dies with ultra-tight tolerances and edge profiles tailored to your exact materials. The result is reduced waste, superior cut quality, and improved line efficiency—delivering consistent performance across every production run.

Why Choose Rototek-Engineered Dies?

At Rototek, precision isn’t just a standard—it’s our foundation. Our dies are engineered with advanced design methodologies, premium materials, and decades of expertise to deliver unmatched reliability and performance. From the first inspection to final delivery, every detail is optimized to enhance cut quality, extend tool life, and maximize production efficiency.

What sets Rototek apart:

Trusted Expertise – A legacy of innovation and technical excellence you can depend on.

Engineering Precision – Ultra-tight tolerances and CAD-verified geometries ensure consistent performance.

Tailored Solutions – Each die is custom-designed to meet your exact product specifications and line requirements.

Durability & Longevity – Material selection, coatings, and proven sharpening techniques extend operational life.

Efficiency in Action – Reduced waste, improved cut accuracy, and faster setups keep your production lines moving.

What Die Chemistry Options Do You Offer?

We provide both evaluation and production services for dies manufactured in a range of specialized materials, including:

Tungsten Carbide

Engineered for maximum durability, tungsten carbide is exceptionally wear-resistant and ideal for cutting and processing highly abrasive materials. It offers superior longevity and performance in demanding production environments.

Powdered Metal

A versatile and cost-effective solution, powdered metal provides a balance of strength, toughness, and durability. It is well-suited for applications that require consistent performance across a wide range of production needs.

Tool Steel

Known for its reliability and value, tool steel is a durable and economical choice. It delivers consistent results and dependable performance when working with a broad variety of materials.